ReVOC4LIFE approach

The challenge of ReVOC4LIFE is to demonstrate a more environmentally sustainable process, that

allows to tanning district companies to be fully compliant with EU Directives on emissions, maintaining

a positive balance between product performance and environmental concerns, with a positive

economic impact.

ReVOC4LIFE focuses on a short-term VOCs remediation solution able to achieve a further reduction of

VOCs emissions, with minimal impact on cost thanks to (1) solvent recovery and closed loop reuse, (2)

to the use of a tanning industry by-product as sorbent appropriately activated.

At State-of-the-Art very efficient abatement systems are built on the spray booths to capture the

powders, pigments, and solvents soluble in H2O but fail, due to the specific nature, of capturing the

VOCs that flow directly into the atmosphere as vapours. Beneficiaries have developed and validated at

TRL7 a new modular system for VOCs emissions abatement and solvent recovery based on air filtering

and electro-oxidation.

This new concept is based on three pillars: (1) closed loop reuse of water from wet scrubbers, thanks to

electro-oxidation, (2) air VOCs adsorption on sintered granules, by-product of excess sludge treatment

similar to activated carbons, (3) solvent recovery from exhaust filters for re-use in tanning process

A full scale pilot plant will be installed in a tannery and operated for one year, covering all the airflow of

a chimney stack, the most critical in terms of VOCs emissions. The baseline for this plant is an air flow

of 20 000 Nm³/h, a current VOCs emission of 5700 kg/y (considering an average MW of 79 the CO2

equivalent emission is 44/79*5700=3200kg/y), and fresh water consumption of 231 m³/y.

The plant can be easily replicated in other lines of the tannery, in other companies of the district, in the

global market, with a huge potential impact: VOCs emission from the tanning district of Santa Croce

sull’Arno alone are estimated to be approximately 5 million kg per year, of which approximately 40,000

kg are produced by the tannery installing the pilot plant.

Comparison with alternative technologies

The main technologies available today are listed here below with indication of the main disadvantage

ReVOC4Life will be overcoming:

(1) Thermal oxidation with burners: VOCs are oxidized to CO2 and H20 in high temperature >750 °C

(with 3200 kg/y CO2 emissions from VOCs, 800 kg/y CO2 emissions from fuel, 25 m³/h CNG, with

secondary pollutants to be treated as NOx and PM2.5, all these emissions would be avoided by

ReVOC4Life), in this application the VOCs concentration are very low (100-200 mg/m3) and the air flow

rates are high, so there is a disproportionate cost for the actual effective benefit.

(2) Catalytic oxidation with burners, where preheated exhaust gas is in contact with a porous catalytic

active material, it is a faster and flameless method with operation temperature >300 °C (anyway with

3200 kg/y CO2 emissions and higher OPEX due to the monitoring/pretreatment of gas to avoid catalyst

poisoning)

(3) Adsorption on activated carbon (AC), this method requires lower temperatures but it is usually non

affordable due to the high cost of activated carbon both in terms of raw material and in management.

In case of regeneration this is an additional cost and the process is usually thermal, with the same

quantity of CO2 emissions (1)

(4) Absorption, where soluble gas components are separated from the gas stream by dispersing it with

the dissolving liquid, This method is only partial and needs anyway to be coupled with (1-3) since

removal efficiency is usually lower than 50% and it is more expensive both in terms of OPEX and

CAPEX.

(5) Biofilters, using living material to capture and biologically degrade process pollutants, it is a method

unsuitable for so high air flows (typical big/scale installations are 200 m³/h) and very inflexible and

sensitive to poisoning.

(6) Cryocondensation, where organic compounds are recovered from liquid after the exhaust gases are

condensed for total recovery, This method finds practical application where the volumes of air to be

treated are very low and the VOC concentrations are very high, otherwise the system is uneconomical

(CAPEX >10M€ for this baseline) and would require a significant amount of energy.

Compared to these alternatives ReVOC4Life is competitive, combining massive abatement (not

possible with 5,6) with lower emissions (compared to 1,2) and lower cost (OPEX up to -30% compared

to the less expensive of the above mentioned). CAPEX target is <80k€ for the baseline (22000 Nm³/h)

comparable to the less expensive of the above (4). The regenerative pressure swing adsorption on KEU

is a breakthrough compared to current practice on (3) where saturated sorbent is usually a chemical

waste.

The project will be implemented in the following Member State(s) and Region(s) or other countries:

Italy

Toscana, Piemonte

Expected start date: 01/09/2021

Expected end date: 31/08/2024

LIST OF BENEFICIARIES

- SIME srl

- Consorzio Aquarno SPA

- BCN concerie spa

- Compolab Srl

- IRIS s.r.l.

- Dipartimento di Ingegneria Civile e Industriale, University of Pisa

PROJECT BUDGET AND REQUESTED EU FUNDING

|

Total project budget: |

3,328,628 Euro |

|

Total eligible project budget: |

3,298,628 Euro |

|

EU financial contribution requested: |

1,814,245 Euro (= 55.00% of total eligible budget) |

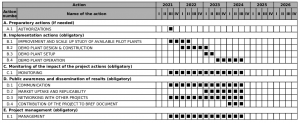

TIMETABLE